In welding work, safety is paramount, and ensuring clear vision isn't just a matter of convenience—it's a matter of livelihood. Whether you're a seasoned welder or a novice apprentice, knowing how to properly care for your welding equipment is crucial to maintaining clear vision and optimal safety on the job. In this guide, we'll delve into detailed steps and tailored advice specifically for welders to effectively clean and maintain their welding lenses and hoods.

(1) Maintain Good Habits:

1. Treat your tools with respect:

Avoid unnecessary rough handling, like dropping them or leaving them in dirty places. A gentle touch goes a long way in preserving their integrity.

2. Steer Clear of Extreme Environments:

Just as you protect yourself from the heat and sparks of welding, your lenses and helmets need protection from extreme temperatures. Avoid leaving them in places prone to rapid temperature changes, like scorching car interiors or frigid glove compartments. Store them in a cool, dry place to maintain their stability and lifespan.

3. Respect Thermal Dynamics:

Glass lenses are sturdy but have their limitations. Avoid subjecting them to rapid heat changes, as this can cause stress and potential damage. If your lenses are hot after extended use, let them cool naturally before cleaning or handling. Likewise, if they feel cold, give them time to slowly warm up to prevent rapid heating and potential lens breakage.

(2) How to Clean and Maintain:

Step 1: Gather Necessary Supplies

Before beginning the cleaning process, gather the following supplies:

-Welding hood and lenses that need to be cleaned

-Soft lint-free cloth and a regular soft cloth

-Use water; mild, non-alkali; non-acidic; soap or detergent (Or you can buy Lenspen or Clearwipe on Amazon)

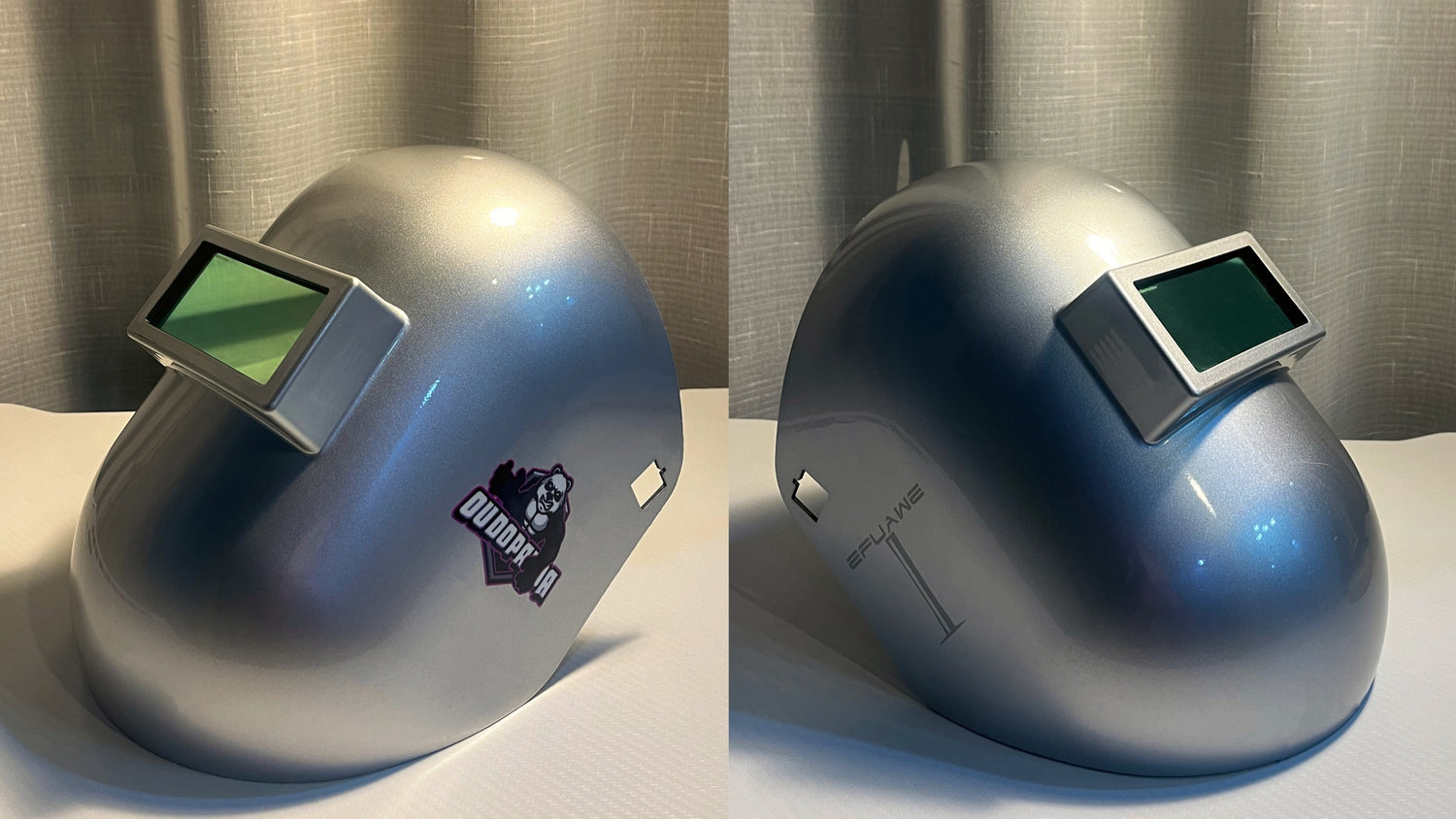

Step 2:Disassemble the hood

To make cleaning easier, remove the lenses, protectors, etc. from the hood.

Step 3:Preparing the cleaner

Using a non-alkaline, non-acidic cost, create soapy water in warm water for cleaning welding tools by wetting a large blue rag in the picture. (Or you can buy Lenspen or Clearwipe on Amazon as cleaner)

Step 4&5&6:Cleaning

Start by checking your welding lens and helmet for any visible debris, such as dust, dirt, or spatter. Gently wipe the hood&lens&protector surface to remove grease, oil, or stubborn residues. Ensure thorough cleaning without applying excessive pressure to avoid distortion or scratching.

Step 7&8: Rinse and Dry

After cleaning the hood&lens&protector, rinse it thoroughly with clean water to remove any soap or residue. Gently pat the lens dry with a clean microfiber cloth to prevent water spots or streaks. Ensure the lens is completely dry before reassembling it into the welding mask.

Well down, now you got a pretty new hood and lens!

Tips:

Take a moment to inspect the lens for any signs of damage, such as scratches, cracks, or pitting. If significant defects are noticed that compromise visibility or safety, consider replacing the lens promptly to maintain optimal protection during welding operations.

Establish a routine cleaning schedule to ensure your welding lens and mask remain in peak condition. Depending on usage frequency and environmental factors, aim to clean your lens after each welding session or at least once a day. Regular maintenance prolongs equipment lifespan and enhances job safety.

In the demanding field of welding, maintaining clear vision is essential. By following these simple yet critical steps, you can ensure your welding lenses and helmets are kept in optimal condition, providing the clarity and protection needed to excel in your craft. So, treat your lenses and hoods with care, and they'll look out for you in return. Happy welding!

1 comment

Roque Cruz

Increíble sus historias! Y muy inspiradoras.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.