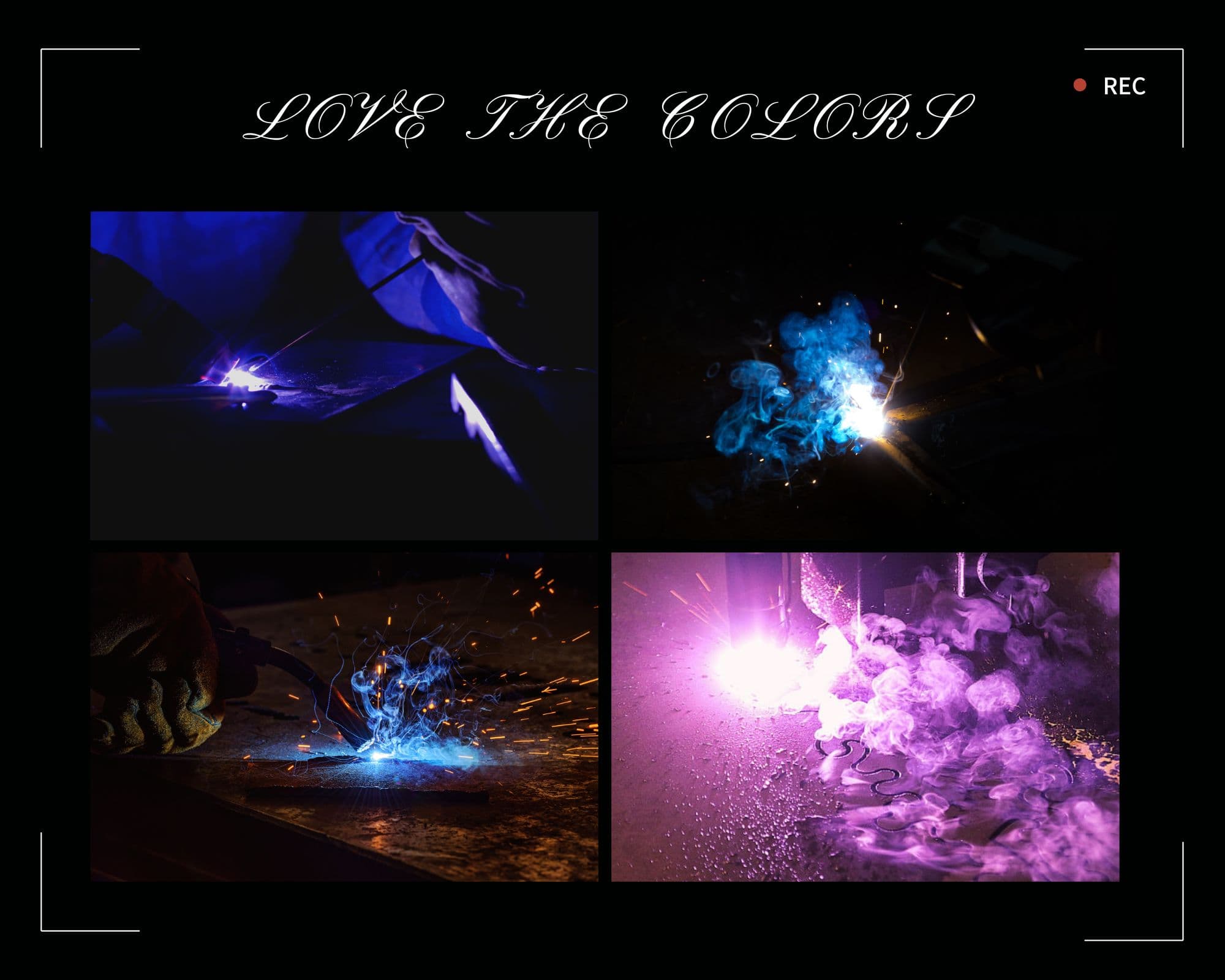

During the welding process, ultraviolet (UV) and infrared (IR) rays are generated which are harmful to the eyes. These rays are invisible to the human eye, but if they are not properly protected, they can cause serious eye injuries or, worse still, blindness. Welding safety glasses are based on optical glass and use colorants such as iron oxide, cobalt oxide and chromium oxide. In addition, a certain amount of cerium oxide is added, which can block 99.9% of red UV/IR rays.

OPTICAL CLASS (ACCURACY OF VISION) 3/X/X/X

Do you know how distorted something can look through water? That's exactly what this class is about. It rates the degree of distortion when looking through the welding helmet lens, with 3 meaning you see as if through rippled water, and 1 meaning there is virtually no distortion - practically perfect.

DIFFUSION OF LIGHT CLASS X/3/X/X

When you spend hours looking through a lens, the smallest scratch or chip can have a big effect. This class rates the lens according to manufacturing defects. 1 means that it is free of impurities and exceptionally clear.

VARIATIONS IN THE LIGHT TRANSMISSION CLASS (LIGHT OR DARK AREAS WITHIN THE LENS)X/X/3/X

Oudopanda passive lens shade offer #9; #10, #11, #12. This class rates the consistency of shade across different points of the lens. Basically, you want the tint to have a consistent level from top to bottom and left to right. A level 1 will provide an even shade throughout the entire lens, while a 2 or 3 will have variations in different areas of the lens, possibly making some areas too bright or too dark.

ANGLE DEPENDENCE ON LUMINOUS TRANSMITTANCE CLASSX/X/X/3

This class rates the ability of the lens to provide a consistent level of shade when viewed from a specific angle. (This is because welders have to weld at different angles in different work situations, e.g. pipe welding, backside welding, etc). This assessment is therefore particularly important for anyone welding in hard-to-reach places. It checks whether the view is clear, without stretching, dark areas, blurring or problems when viewing objects at a certain angle. A rating of 1 means that the shade stays consistent no matter the viewing angle.

(6). Precise control of shade number within ±0.2

All Oudopanda brand passive glass raw materials are triple tested manually + with a European machine + with self-developed instruments to ensure that the shade number of the passive glass in your hands is precisely within the ±0.2 variation range. (When testing most other passive glasses on the market and even the auto-darkening welding lens, we were surprised that the shade number of most products is much more than ±1, which means, it is advertised as shade 9, but in reality it is between 10 and 11!) ). When selecting the raw materials, 20% of the passive glass has already been sorted out, which is an amazing figure!

(7). Minor errors in the control spectrum

Each Oudopanda passive glass has its own fixed spectrum. We are also equipped with professional spectral testing equipment and have developed our own software, together with strict screening by our staff, ensures that every piece of our colored passive glass has stable performance, excellent quality and low color difference error.

Dear welder friend, I am glad you stopped by. Although we want to make our products as perfect as possible, but probably there are still details that have not been taken into account. We would be delighted if you could make suggestions with us to make the product the way you want it.

What additional functions would you like to see in our product? Write us a comment in the comments section below.

For those who make suggestions, we will select one person to give away 1 piece of colored passive glass and 5 pieces of branded stickers. We look forward to your feedback and suggestions----From Oudopanda Team

7 comments

Logan Goodwin

True color with gold coating

Curtis

Purchased a true color and magenta, love them both! Would love to see a red puddle!

Pt

How about a crimson, purple, gold lense

Filippo Sorino

Hello, is it possible to buy two blue glasses? How can I do it?

Alex

I would like to see a yellow or amber colored lens. I have a polycarbonate amber colored lens and really like the color but the detail and clarity is way below any glass lens

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.